At Rapid Kraft, our 3D Printing services offer precision and flexibility to bring your concepts to life. Whether for prototyping, product development, or custom manufacturing, our advanced capabilities make it possible to produce parts with fine details and exacting quality. Using technologies like FDM (Fused Deposition Modeling) and SLA (Stereolithography), we deliver prints that meet diverse specifications, ensuring you get the durability, flexibility, or intricacy you need for any project.

Our efficient 3D printing process allows for rapid prototyping and small-batch production, providing quick turnaround times so you can test, iterate, and refine your designs faster. From complex architectural models to functional parts, we support you at every stage with high-quality, customizable prints that help turn ideas into tangible products.

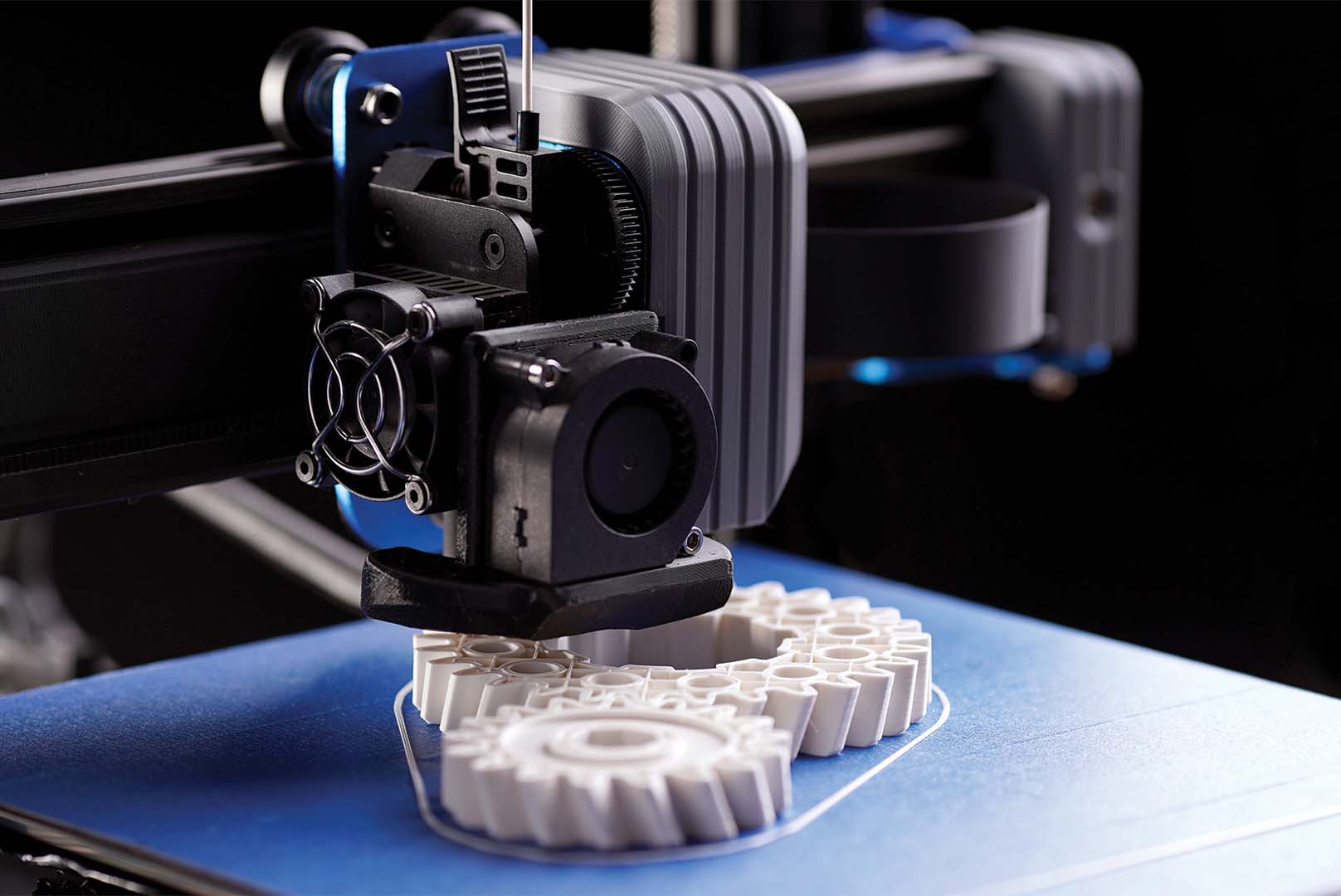

FDM is a popular 3D printing method that constructs objects by heating and extruding thermoplastic filament, layer by layer. It's known for being cost-effective, versatile, and easy to use, making it ideal for both prototyping and manufacturing. FDM is widely used across industries such as automotive, aerospace, and consumer goods for creating functional parts and models.

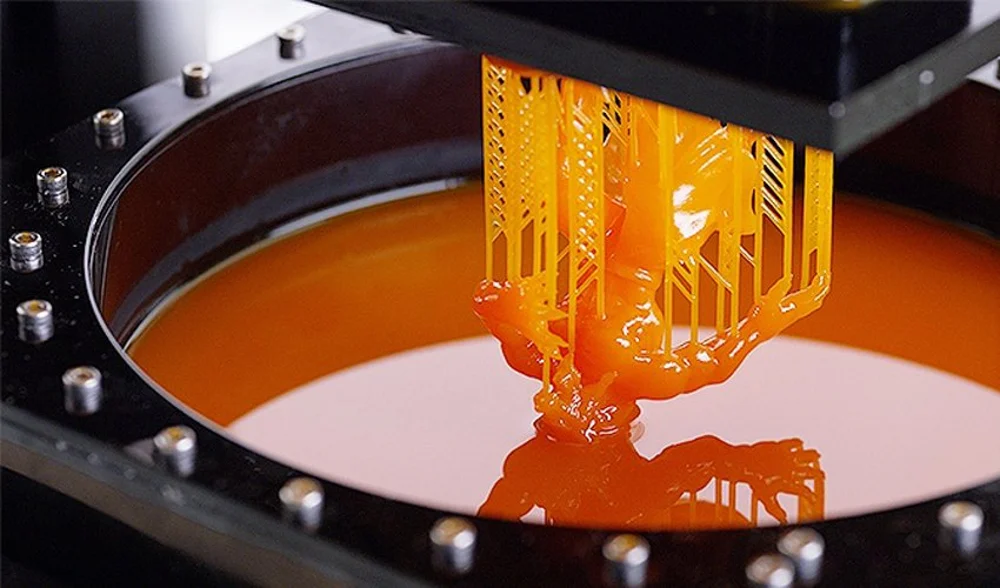

Uses a laser to cure liquid resin into solid layers. Known for high precision, it's ideal for detailed parts in prototyping, jewelry, and medical applications.

SLS is a 3D printing method that uses a laser to fuse powder layers, creating strong, detailed parts ideal for complex designs and functional prototypes.

Digital Light Processing (DLP) is a 3D printing technology that uses a digital projector to cure photopolymer resin layer by layer. Known for its high speed and precision, DLP produces highly detailed and smooth parts. It is widely used in industries like medical, dental, and jewelry for rapid prototyping and manufacturing.

FDM is one of the most common 3D printing technologies, ideal for producing durable prototypes and functional parts. This process involves melting and extruding thermoplastic filaments layer by layer, allowing for the creation of complex geometries with high strength-to-weight ratios. FDM is perfect for projects requiring robustness and quick turnaround times.

SLA utilizes a laser to cure liquid resin into hardened plastic, offering exceptional detail and surface finish. This method is suitable for intricate designs and is often used for high-resolution prototypes, models, and small-batch production. SLA parts exhibit excellent accuracy and are ideal for industries that demand high-quality visual presentations.

SLS employs a laser to fuse powdered materials, such as nylon or metal, into solid structures. This technique allows for the creation of complex geometries without the need for support structures, making it ideal for functional prototypes and end-use parts. SLS is known for producing strong, durable components suitable for a variety of applications, including automotive and aerospace.

Similar to SLA, DLP uses a light source to cure resin, but it projects an entire layer at once, making it faster than traditional SLA methods. This technology is excellent for creating highly detailed models and parts with smooth finishes, often used in jewelry and dental applications.

MJF is a cutting-edge technology that uses an inkjet array to apply a binding agent to layers of nylon powder, followed by heating to fuse the particles. This process allows for the rapid production of functional prototypes and production parts with excellent mechanical properties and intricate details.

At Rapid Kraft, our 3D Printing services transform ideas into reality with precision and versatility, providing tailored solutions across prototyping, product development, and small-batch production. Utilizing advanced technologies like FDM and SLA, we ensure each part meets exact specifications, offering flexibility in material choice and design complexity. Whether you need a durable, functional prototype or a detailed model, our processes deliver high-quality prints that suit a variety of applications.

Our team emphasizes efficiency and speed, making our services ideal for rapid prototyping. This allows clients to test, iterate, and finalize designs in a fraction of the time required by traditional manufacturing methods, ultimately reducing development costs and time-to-market. We provide material guidance and expert support from start to finish, ensuring that each print is optimized for both function and aesthetic.

Beyond printing, Rapid Kraft offers a range of post-processing services, including sanding, painting, and assembly, to meet the demands of end-use applications and high-quality presentations. Committed to sustainability, we also provide eco-friendly material options to reduce environmental impact. Serving industries from automotive to healthcare, we empower our clients with innovative, efficient, and reliable 3D printing solutions that elevate their products and ideas.

For all over India

Confidence on all your devices

24 x 7 support

money back guranry