At RAPID KRAFT Engineering

Services,

we specialize in turning innovative ideas into reality. With

expertise in 3D printing, metal machining, vacuum casting, and custom fabrication,

we provide high-quality solutions for individuals and businesses alike. Our

commitment to precision and creativity ensures that every project meets your unique

needs. Whether you're looking for prototypes, personalized gifts, or support for

college projects, we’re here to help you succeed!

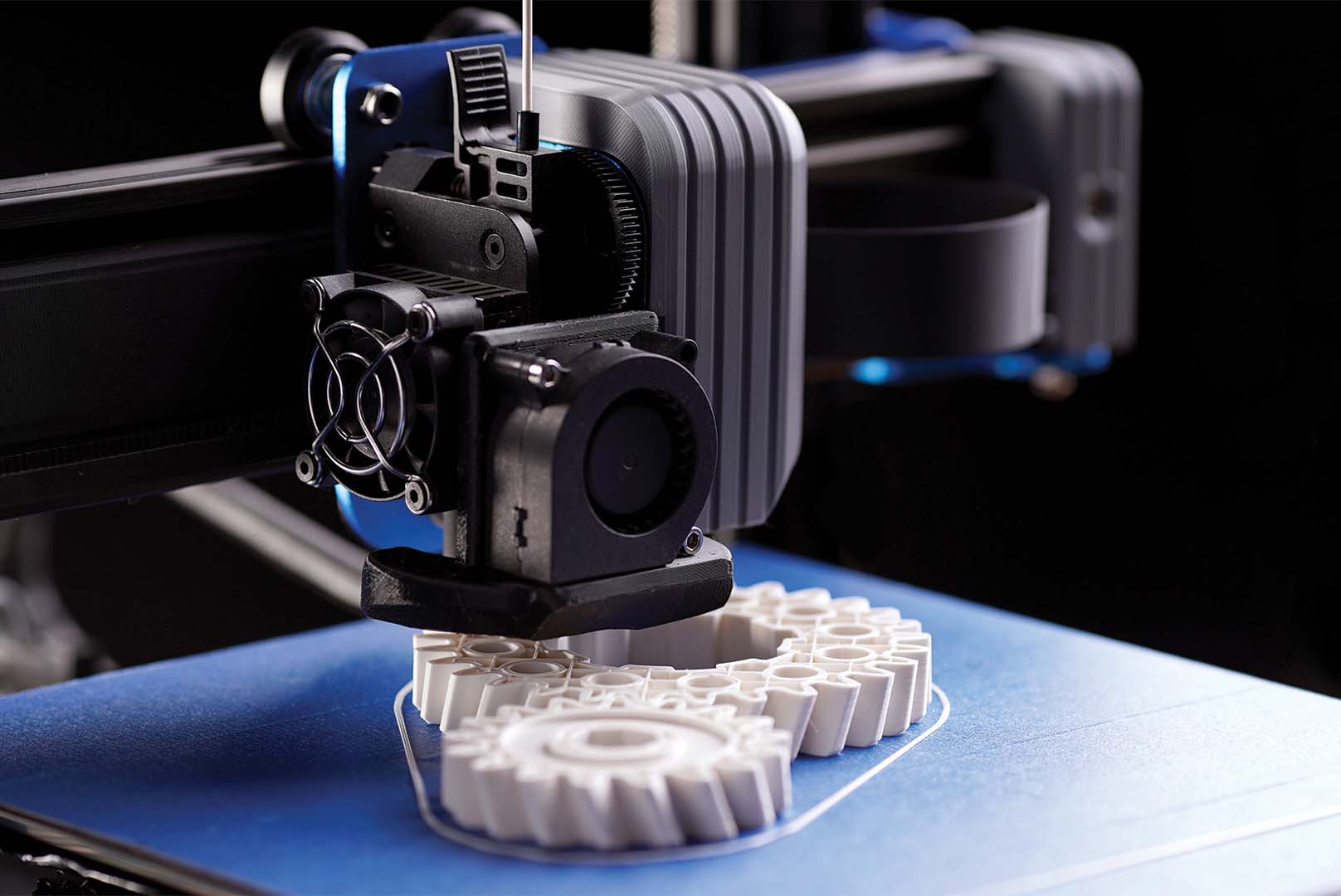

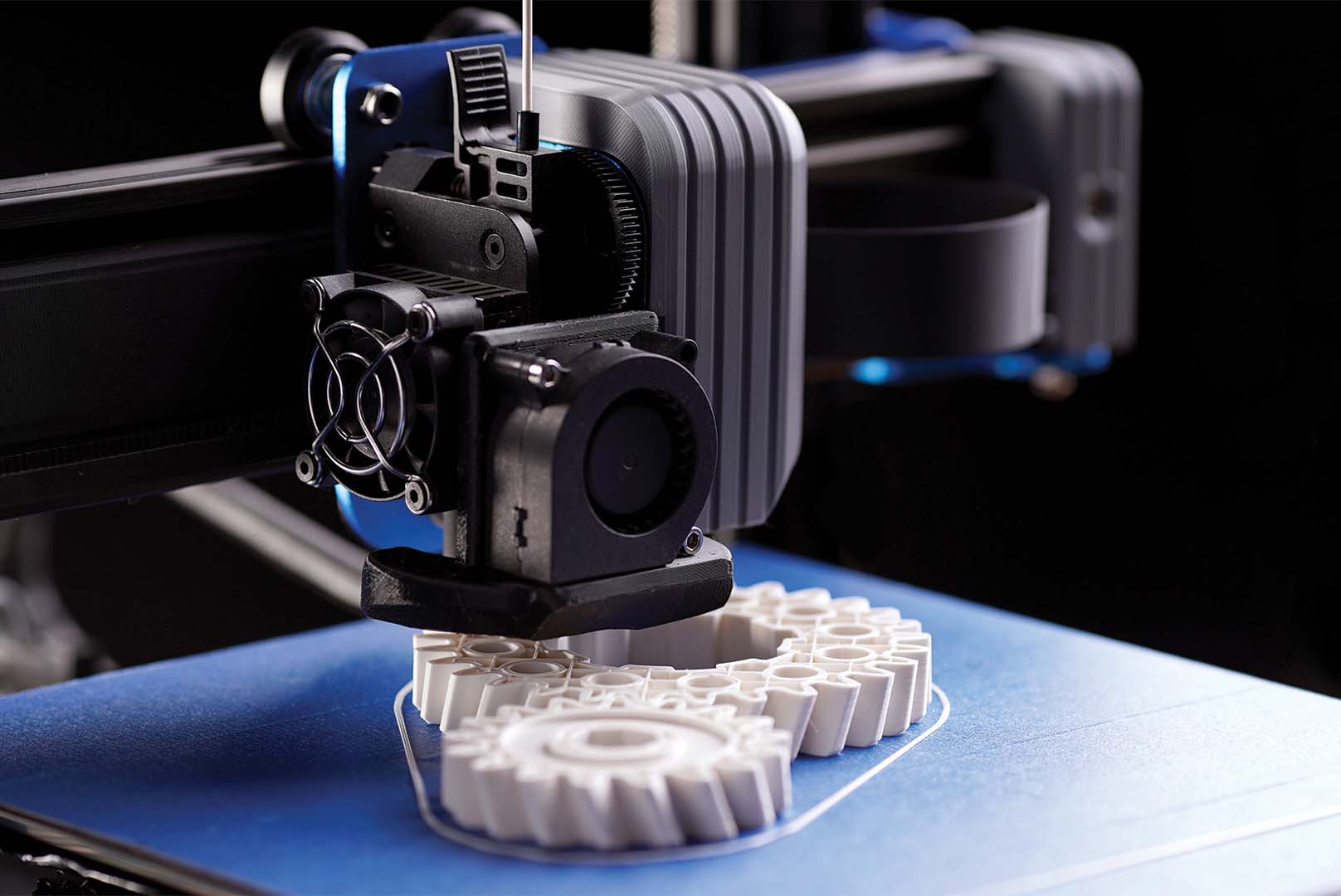

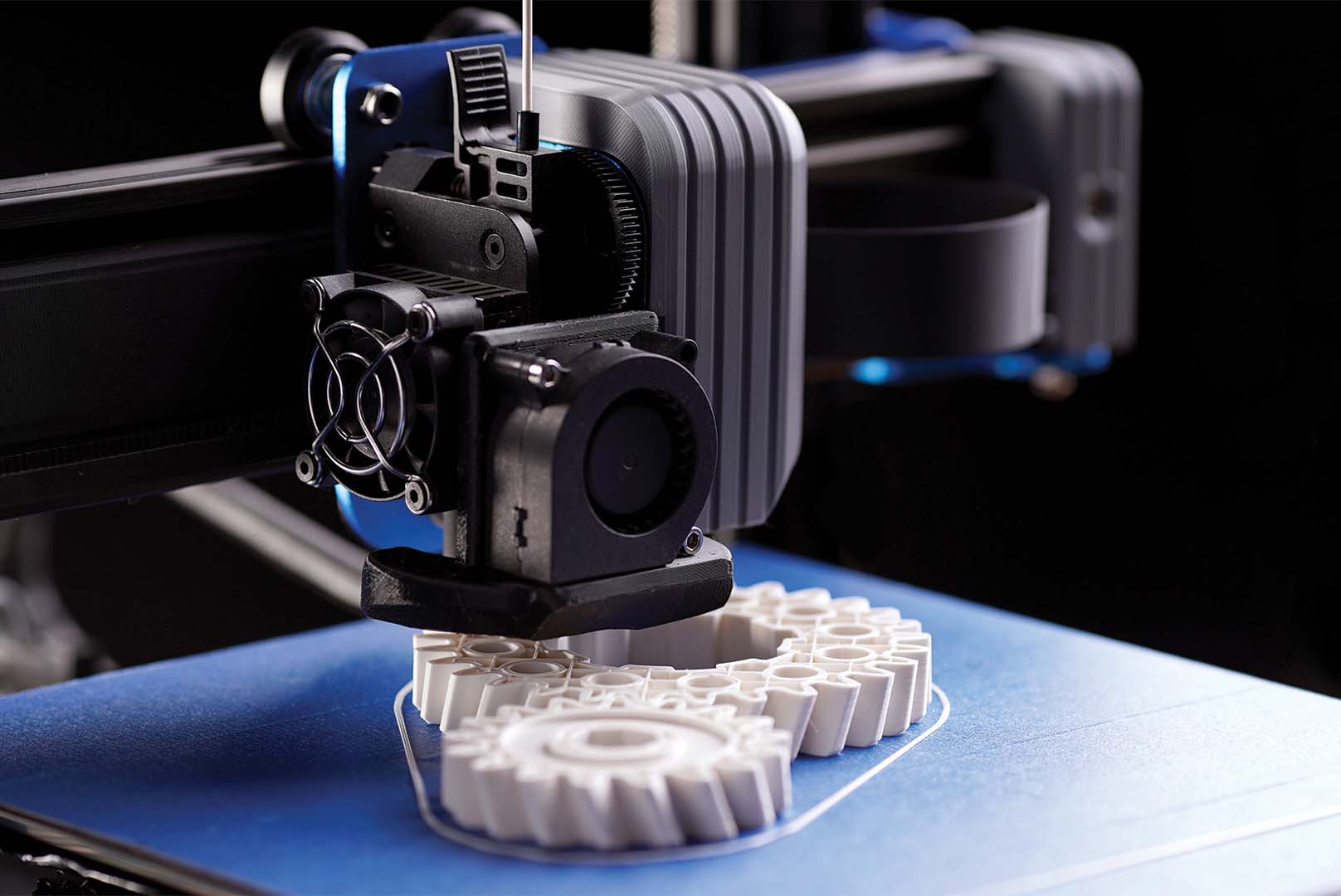

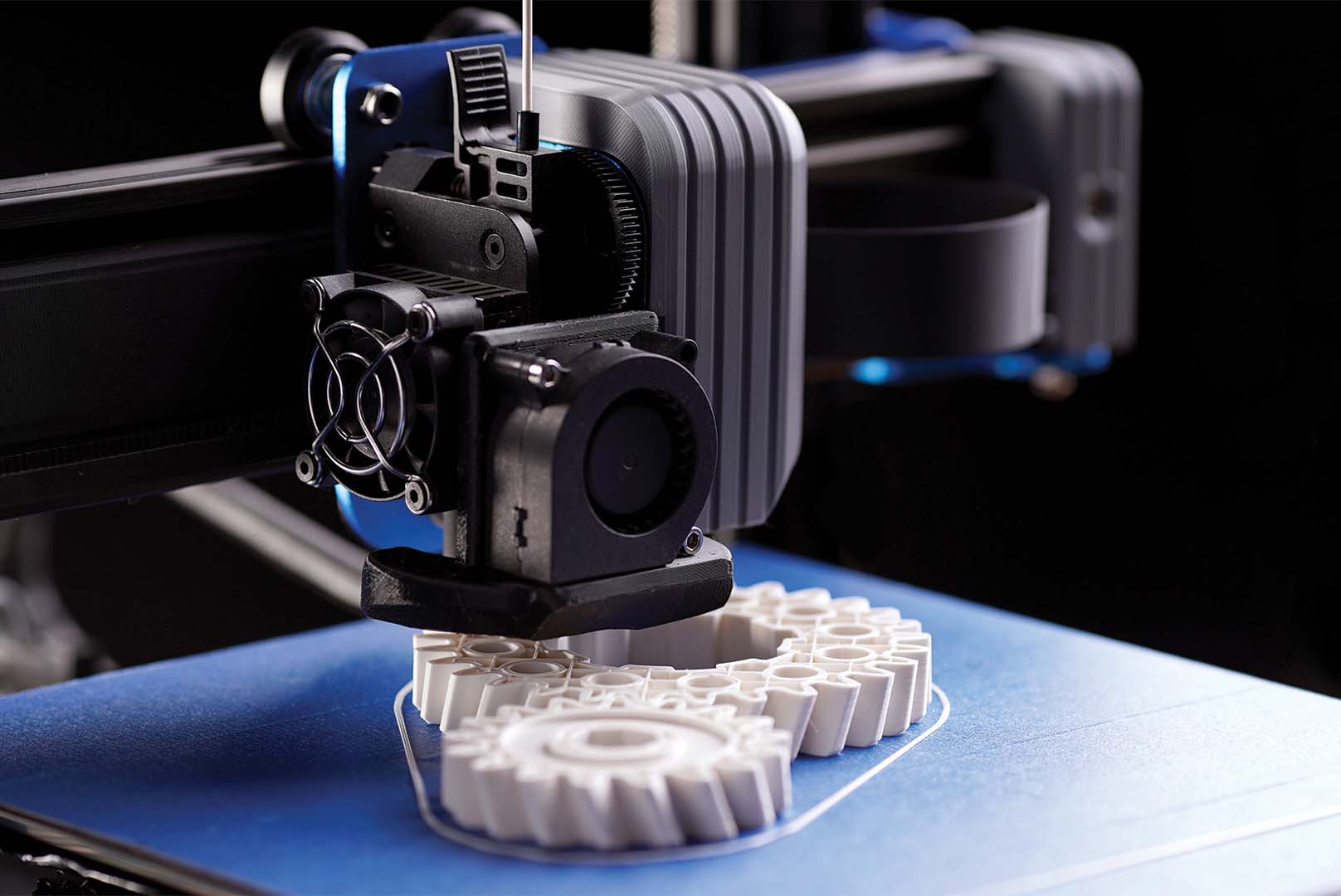

We offer a range of advanced 3D printing options, including FDM, SLA, and DLP, to bring your ideas to life with precision and quality. From rapid prototyping to final product manufacturing, our services cater to diverse industries and custom requirements. Achieve high-detail, durable results with our state-of-the-art 3D printing solutions.

READ MOREUses a laser to cure liquid resin into solid layers. Known for high precision, it's ideal for detailed parts in prototyping, jewelry, and medical applications.

READ MORE

A popular method for prototyping, FDM melts thermoplastic filament and layers it to build objects.

READ MORE

DLP uses a digital light projector to cure resin with high precision and speed, creating smooth, detailed parts ideal for applications like dental models and jewelry. Its fast, consistent process is perfect for intricate designs..

READ MORE

Emphasize the team's creativity and technical skills in bringing ideas to life.

Highlight software and technology expertise, like CAD tools, used to create detailed designs.

Focus on user-centered design practices and customization based on client needs.

Describe the range of materials and printing technologies available (e.g., FDM, SLA).

Highlight fast turnaround times for prototyping and small-batch production.

Mention the quality and precision of 3D prints and how it supports innovation.

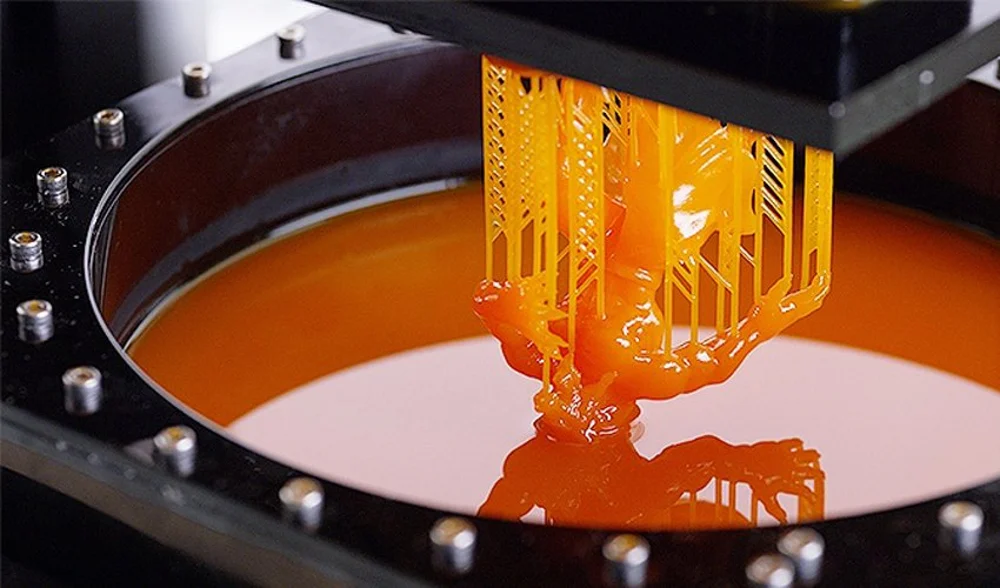

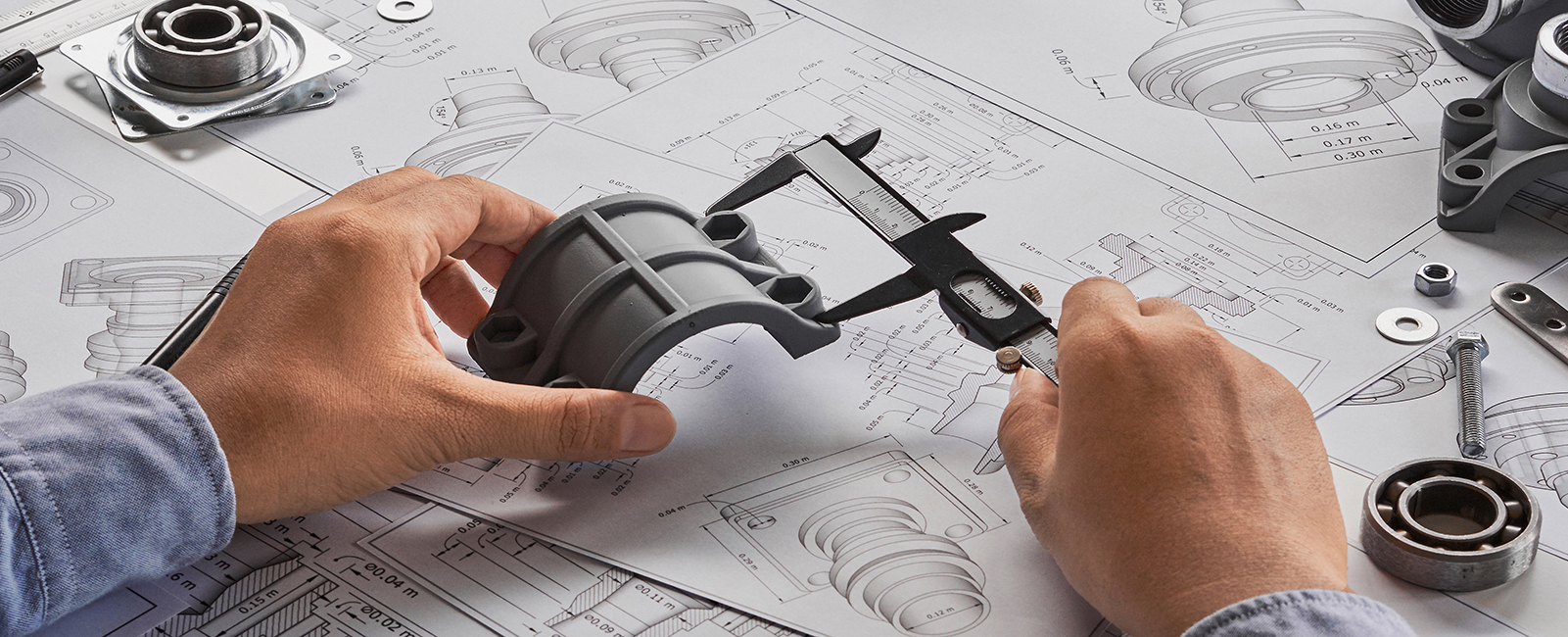

Detail the precision and capability to create complex metal components.

List types of metals used and machinery involved (e.g., CNC machining).

Highlight its applications in industries like automotive, aerospace, and custom fabrication.

Explain how vacuum casting is used for producing high-quality, durable plastic parts.

Emphasize affordability and quality, especially for prototypes and small production runs.

Mention its flexibility with materials and textures, ideal for product testing.

Describe the processes (cutting, bending, welding) and machinery involved.

Mention durability, precision, and use cases (e.g., enclosures, brackets, chassis).

Highlight the company’s ability to handle custom designs and various metal types

Highlight expertise in aerodynamics, electronics, and materials specific to drone and RC plane construction.

Discuss possible applications like aerial photography, mapping, and custom hobby projects.

Mention customization options and design-to-flight support.

Describe unique and customizable gift options, like personalized figurines, models, or keychains.

Highlight quality, intricate detailing, and a range of materials and colors.

Emphasize the one-of-a-kind, memorable nature of 3D-printed gifts.

For all over India

Confidence on all your devices

24 x 7 support

money back guranry